How to Remove Rust and Battery Stains

Understanding the Different Types of “Rust”

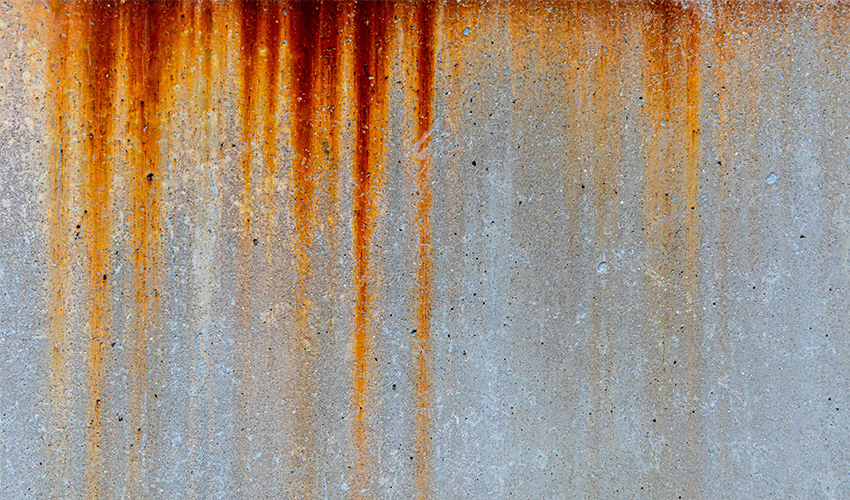

Rust comes in a variety of forms – iron oxide, iron hydroxide, and green rust, to name a few. It can also form on a variety of surfaces. The more porous a surface is, the deeper the rust can penetrate, and the more difficult rust removal can be.

Iron oxide is a simple a yellowish rust that is thin and watery that results from high moisture content, and can usually be safely removed using oxalic acid. But as rust goes through different stages, it can get tougher to remove. Iron hydroxide (II and III) – which is a metallic, flaky, corrosive for of rust – forms a more concentrated buildup.

Then there are those stains that look like rust but are not actually rust. For example, battery stains from electric vehicles like golf carts, are the result of an orange flash acid burn from the sulfuric battery acid. These stains look like rust, but they are very different. They also grow in both length and depth, making them difficult to remove without the right product.

How to Safely Remove Rust, Orange Battery Stains, and Fertilizer Stains from Concrete

Most traditional rust removers are made of acids that remove the stains by eating away the stained concrete. Not only does this strip the concrete of its cement paste, they can leave an etched surface around where the stain was removed. They also only remove the surface rust which permanently damaging the concrete.

This is why we recommend the Front 9 (F9) group of products for rust and orange acid burns, such as from batteries and fertilizer stains, from concrete, bricks, pavers, stone, stucco, vinyl siding, concrete coatings, pool decks, roof shingles, asphalt, rubber, and other surfaces without causing damage.

Pre-Cleaning with F9 Double Eagle

Power wash concrete using a commercial grade pressure washer, degreaser, and surface cleaner. Cleaning the concrete first will open up the pores of the concrete and allow F9 BARC to soak in deeper and remove more of the orange battery stain than just applying F9 BARC alone.

For this, Front 9 Double Eagle Degreaser is both great for degreasing and general cleaning. It can also be used for neutralizing acidic products like F9 Efflo and F9 BARC. Double Eagle is bleach stable and works well in house wash mixes as well.

If there are oil stains in combination with battery acid stains, F9 Double Eagle will clean the oil and concrete and neutralize the battery acid. After applying F9 Double Eagle, you will need to surface clean like you would with any other degreaser.

After you finish washing, let the concrete completely dry.

F9 BARC (Battery Acid Restoration Cleaner)

For the actual rust removal, we recommend using F9 Barc, which is specifically formulated to remove both battery acid staining and rust stains. This includes the entire spectrum of the rust family: thin, thick, topical, embedded, and fertilizer staining. F9 BARC chemically locks into the concrete, reversing 80 to 100% of the orange staining and restores concrete to its natural bright gray color. BARC is easy to apply and does not require scrubbing, brushing or elbow grease. BARC is ready to go upon arrival and does not require mixing.

Appying F9 BARC to Concrete

Use a 1:2 dilution ratio (1 part water, 2 parts F9 BARC), apply BARC liberally and evenly using a sprayer to the entire pad of concrete using pressure at 60-70 psi. We recommend the ProTool Power Sprayer, which is one of the most versatile and easy-to-use sprayers on the market and sprays up to 90 psi.

Do not "spot spray" for your first application. Also, it is better to go heavier on your first application, and lighter if you have to redo the application to remove more stubborn stains. Use a circular, overlapping spray motion. Apply as evenly and as thick as possible without letting F9 BARC run down the concrete. If F9 BARC does run down the concrete, leave it alone. F9 BARC should begin to turn white and foam slightly. Then go back and apply a bit more on areas with more staining.

As the concrete dries, the stains will disappear.

If spots remain, repeat the F9 Barc application process. On the second application, you may use less product on the areas with less staining and more product on the areas with stains remaining. It is acceptable to mist-spray on this application.

A natural by-product of the reaction of this product and the concrete are light and dark mineral salts. To help fix this issue, wet the concrete with water to reactivate the F9 cleaner. While wet, lightly broom the concrete to help F9 BARC penetrate the concrete even deeper. Do not let concrete dry. Rinse LIGHTLY with a pressure washer to remove remaining surfactant. Do not use a surface cleaner here. Allow concrete to dry completely and evaluate results.

Using F9 BARC to Remove Rust and Battery Acid Stains from Non-Cement Substrates

(For Non-Porous Surfaces)

The biggest difference between applying F9 BARC to non-porous substrates or semi-porous substrates is that with non-porous, you do not want the F9 Barc to dry. With porous concrete, the F9 Barlc needs to dry so that it can sink further into the pores. The concentrations of water to F9 Barc varies as well.

For Non-Porous Substrates: Mix 2:1 or even 3:1 water to F9 BARC concentration.

Examples of non-porous substrates include sealed concrete, concrete coatings, clay pavers, tile, painted metal, aluminum (not polished or chrome), stainless steel, interior pools, and other surfaces that do not allow water to penetrate.

For Semi-Porous Substrates: Mix 1:1 or 2:1 water to F9 BARC solution.

Examples of semi-porous include stucco, plastic, vinyl, asphalt, stone, and others.

With the correct mixtures ready to go, follow these instructions:

1. Mist surface so it is damp but not wet. Using a minimum of 2:1 ratio (2 parts water to 1 part F9), mist product on surface. Rust stains should disappear. Repeat if necessary. Rinse with water after stain disappears. Do not use on glass.

2. F9 BARC can be diluted with up to 3 parts water for tile, stone, vinyl and other not so porous surfaces. Always do a test spot to confirm compatibility.