Wiring Pumps Through a Bus Bar, Circuit Breaker and Pump Controller: A Step-by-Step Guide

Wiring Pumps Through a Bus Bar, Circuit Breaker and Pump Controller: A Step-by-Step Guide

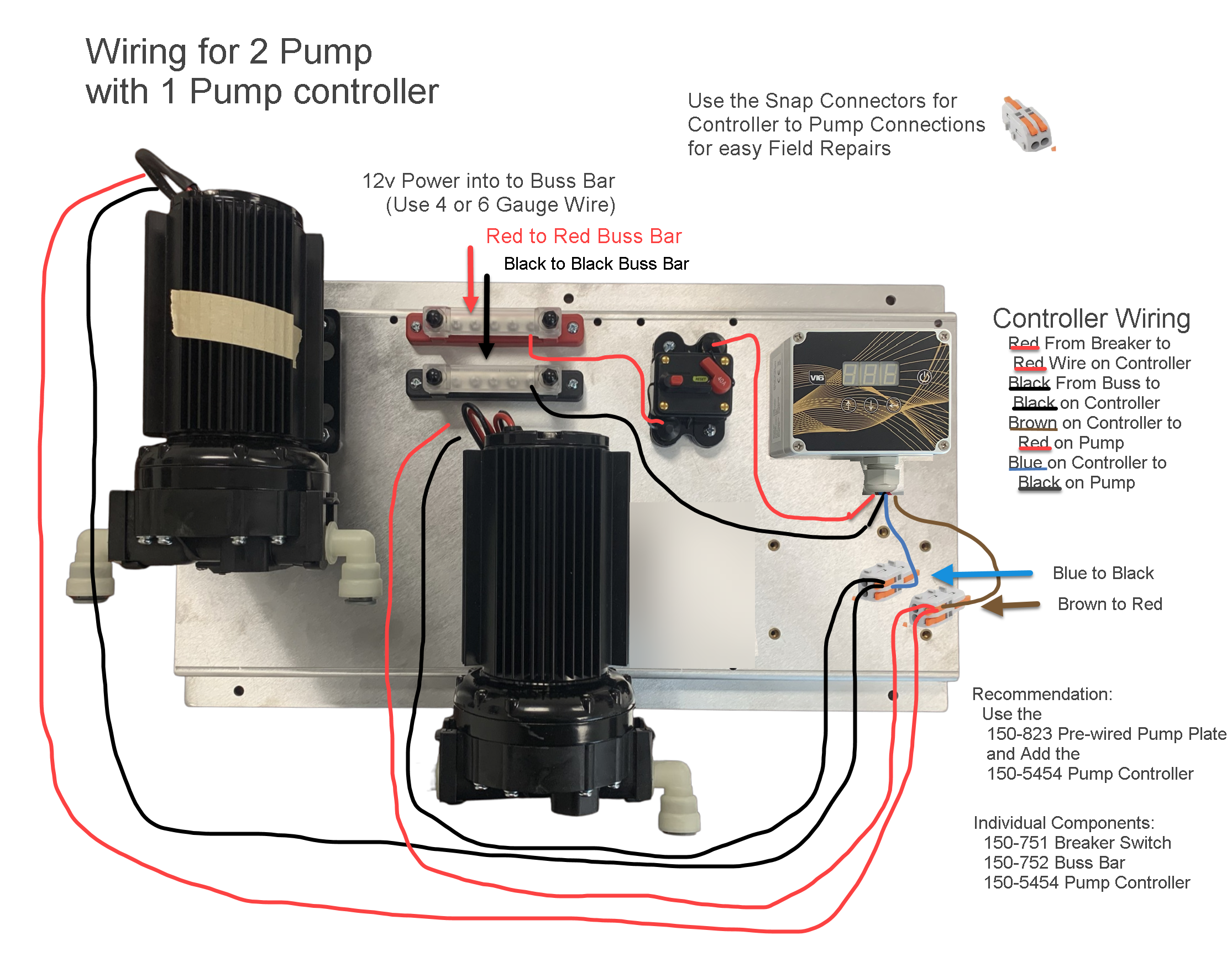

Setting up an efficient and reliable pump system involves proper wiring through a bus bar and circuit breaker. This method ensures safety, reduces power consumption, and extends the lifespan of your pump. Here’s a detailed guide on how to wire your pumps using a bus bar, circuit breaker, and pump controller.

Materials Needed:

- Bus bar

- Circuit breaker

- 4 to 6 gauge wire (from the 12V power source to the bus bar)

- 12 gauge wire (from the bus bar to the breaker and from the breaker to the pump controller)

- Pump controller

- Connectors and terminals

Steps:

- Wiring from Power Source to Bus Bar:

- Use 4 to 6 Gauge Wire: Connect a 4 to 6 gauge red wire from the positive terminal of your 12V power source to the red bus bar. Ensure a secure connection using appropriate connectors.

- Connect Black Wire: Similarly, connect a black 4 to 6 gauge wire from the negative terminal of your power source to the black bus bar.

- Wiring to the Circuit Breaker:

- Use 12 Gauge Wire: Connect a 12 gauge red wire from the red bus bar to the input terminal of the circuit breaker. Then, connect another 12 gauge red wire from the output terminal of the circuit breaker to the red wire on the pump controller.

- Connect Black Wires: Run a 12 gauge black wire from the black bus bar to the black wire on the pump controller.

- Connecting the Pump Controller to the Pump:

- Blue Wire Connection: Connect the blue wire from the pump controller to the black wire on the pump.

- Brown Wire Connection: Connect the brown wire from the pump controller to the red wire on the pump.

Why Use Circuit Breakers Instead of Fuses:

- Resettable Protection: Circuit breakers can be easily reset after tripping, unlike fuses which need replacement.

- Enhanced Safety: They provide more consistent protection and can be manually turned off for maintenance or emergencies.

- Convenience: Reduces downtime as you don’t need to carry spare fuses or deal with frequent replacements.

- Reliability: Circuit breakers are more reliable and less prone to degradation over time compared to fuses.

Benefits of Using a Pump Controller:

- Power Management: The pump controller, such as the V16 HC, is designed to manage pumps drawing up to 35 amps, ensuring efficient performance.

- Reduced Power Consumption: By regulating pump speed, the controller significantly reduces power consumption, saving energy and costs.

- Increased Pump Lifespan: Minimizes mechanical wear, extending the lifespan of your pump through precise control of the flow.

- Precision Control: Provides exceptional accuracy in controlling the output to suit specific needs, enhancing the performance and efficiency of the pump.

Connection Overview:

- Red Wires:

- From the 12V power source to the red bus bar using 4 to 6 gauge wire.

- From the red bus bar to the circuit breaker input with 12 gauge wire.

- From the circuit breaker output to the red wire on the pump controller with 12 gauge wire.

- Black Wires:

- From the 12V power source to the black bus bar using 4 to 6 gauge wire.

- From the black bus bar to the black wire on the pump controller with 12 gauge wire.

- Pump Controller Connections:

- Blue wire from the controller to the black wire on the pump.

- Brown wire from the controller to the red wire on the pump.

By following this setup, you ensure a robust, efficient, and safe electrical system for your pumps. Utilizing a bus bar simplifies wiring and management, while circuit breakers provide reliable and resettable protection, enhancing the overall durability and functionality of your setup. The pump controller further optimizes the system by providing precise control and reducing power consumption.