ProTool 4 User Pure Water Tank System

Quick Overview

- The Pure Water Production System supports up to four operators with its high-capacity water production and storage, featuring a 270-gallon IBC tank for ample supply.

- Produces over 4.5 gallons per minute (GPM) of RO water, ensuring a steady and efficient flow for demanding cleaning tasks.

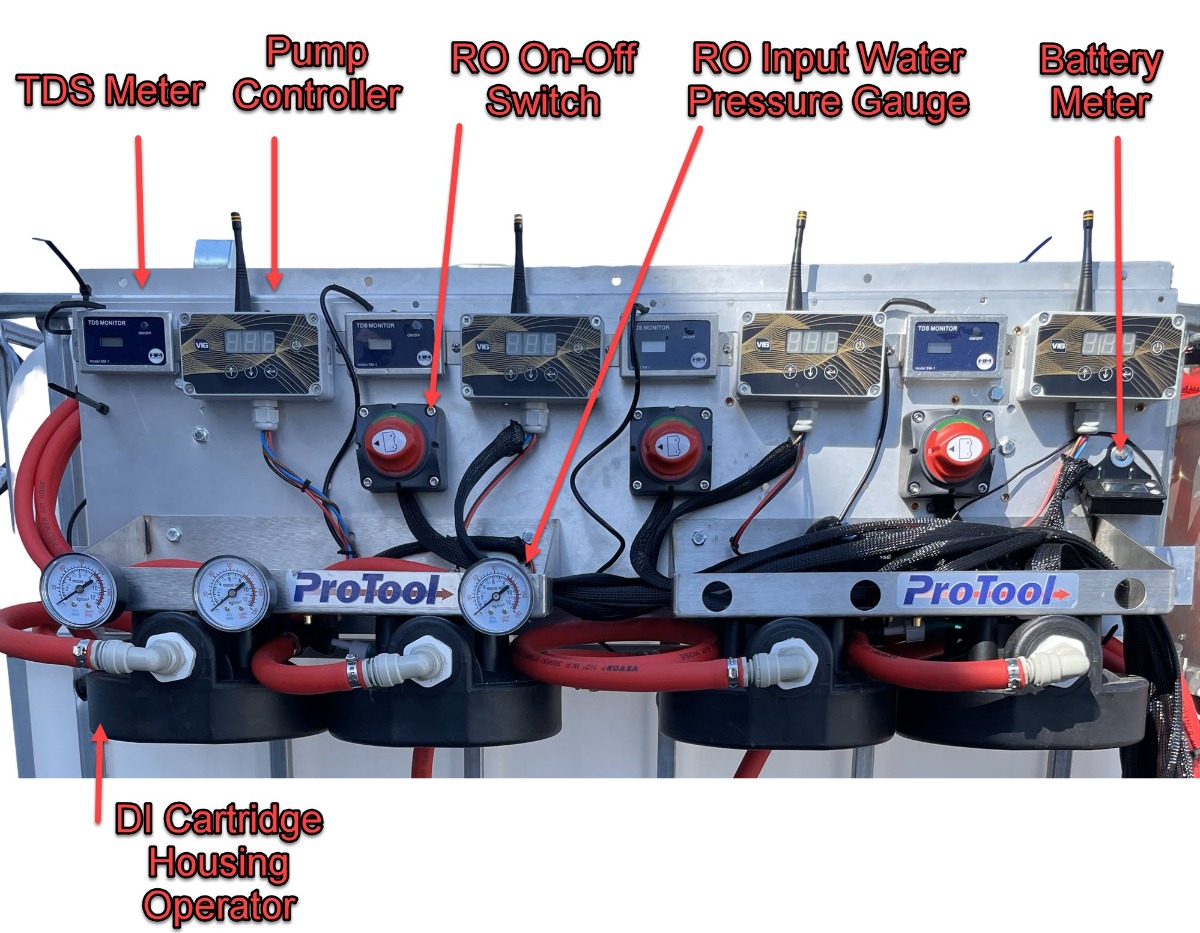

- Each operator is equipped with an independent delivery system, including a pump, pump controller, TDS meter, and DI resin cartridge for precise zero TDS water polishing.

- Designed for robust performance, the system guarantees high-quality water output for multiple operators, enhancing efficiency and effectiveness in Water Fed cleaning operations.

Show More

$6,881.95

$7,968.55

ProTool 4 User Pure Water Tank System

In the world of high-performance cleaning, the Pure Water Production System stands out as an unparalleled solution, designed to meet the needs of busy professionals and commercial operations. Whether you are managing a large-scale cleaning service or overseeing multiple cleaning tasks simultaneously, this system delivers superior water production and storage capabilities to ensure efficiency and effectiveness. Let's delve into the features that make the Pure Water Production System a must-have for any operation requiring reliable and high-quality water.

Superior Capacity and Efficiency

The Pure Water Production System is engineered to support up to four operators, making it an ideal choice for larger teams or high-demand scenarios. At the heart of this system is a substantial 270-gallon Intermediate Bulk Container (IBC) tank. This large tank is designed to handle significant volumes of water, ensuring that you have a steady supply for extended operations. The tank's robust construction and ample capacity minimize the need for frequent refills, allowing your team to focus on their tasks without interruption.

This system’s ability to produce over 4.5 gallons per minute (GPM) of reverse osmosis (RO) water is a game-changer. The high production rate ensures that each operator has access to a continuous flow of purified water, enhancing productivity and reducing downtime. This capability is particularly beneficial for large cleaning jobs or multiple concurrent tasks, where a reliable and substantial water supply is essential.

Independent Delivery Systems for Enhanced Flexibility

One of the standout features of the Pure Water Production System is its provision of independent delivery systems for each operator. This thoughtful design ensures that every operator can work efficiently without being hindered by shared resources. Here’s a closer look at what each independent system includes:

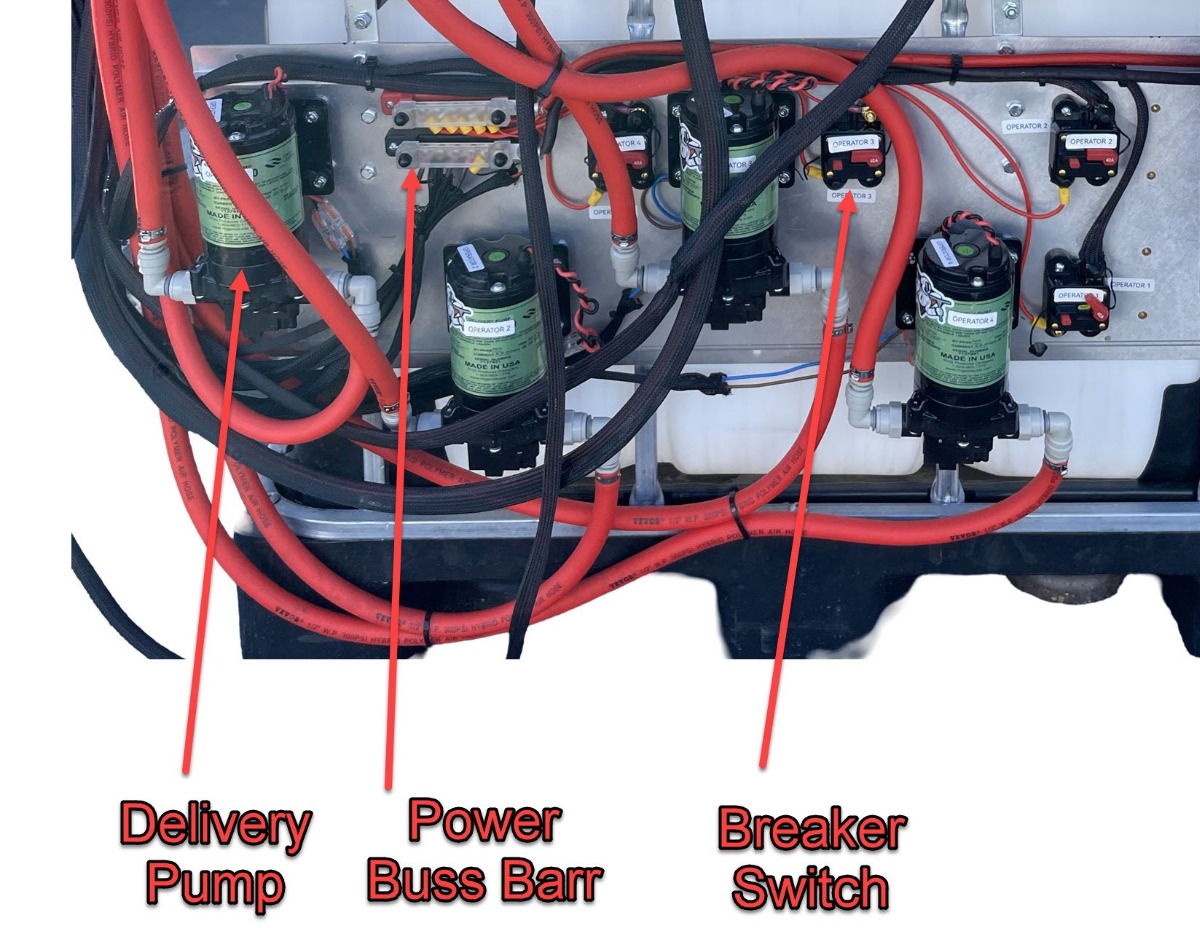

- Pump: Each operator’s delivery system is equipped with a high-performance pump. This ensures consistent water pressure and flow, which is crucial for effective cleaning and achieving the desired results.

- Pump Controller: The pump controller allows for precise adjustment of water flow rates. Operators can easily tailor the water pressure to their specific needs, optimizing the cleaning process and adapting to different tasks or surfaces.

- TDS Meter: The Total Dissolved Solids (TDS) meter is an essential tool for monitoring water quality. By providing real-time readings of TDS levels, it ensures that the water being used meets the required purity standards. This is critical for achieving streak-free and spotless results, especially in sensitive applications like window cleaning.

- DI Resin Cartridge: The DI (Deionization) resin cartridge is used for final water polishing. It ensures that the water reaches a zero TDS level, which is essential for delivering pure water that leaves no residues or spots. This final stage of filtration guarantees that the water used in cleaning is of the highest quality.

High-Quality Filtration for Immaculate Results

The filtration process of the Pure Water Production System is designed to produce water that meets the highest standards of purity. The system employs advanced reverse osmosis technology, which effectively removes impurities, contaminants, and dissolved solids from the water. This process ensures that the water produced is clean, clear, and suitable for a variety of cleaning tasks.

The addition of the DI resin cartridge further enhances the water quality by providing final polishing. This step removes any remaining ions or impurities, ensuring that the water used for cleaning is completely pure. The result is streak-free, spotless surfaces, which is particularly important for tasks that demand a high level of cleanliness and visual clarity.

Practical Benefits for Professional Cleaning

The Pure Water Production System offers numerous benefits for professional cleaning operations. Here’s how it can enhance your cleaning services:

- Increased Efficiency: With the capacity to support multiple operators and high production rates, the system significantly increases operational efficiency. This means that larger jobs can be completed more quickly, and multiple tasks can be handled simultaneously.

- Enhanced Flexibility: The independent delivery systems provide operators with the flexibility to work independently. Each operator can control their own water flow and quality, adapting to the specific requirements of their tasks.

- Consistent Results: The high-quality filtration and zero TDS water ensure consistent and reliable cleaning results. This is crucial for maintaining high standards of cleanliness and achieving the desired outcomes in every job.

- Reduced Downtime: The large capacity tank and high production rates minimize the need for frequent refills, reducing downtime and allowing your team to work more continuously. This is especially beneficial for busy operations where time is of the essence.

- Improved Water Quality: The advanced filtration technology guarantees that the water used is free from contaminants and impurities. This not only enhances cleaning performance but also contributes to the longevity and appearance of the surfaces being cleaned.

Key Features:

- High-Efficiency RO Water Production: Produces over 4.5 GPM of RO water directly into a 270-gallon IBC tank, ensuring ample supply for up to 4 operators.

- Independent Operator Systems: Each operator has a dedicated 1 GPM delivery pump, pump controller, remote control fob, DI resin cartridge, and TDS meter.

- Optimal Performance Conditions: Designed to operate efficiently with inlet water pressure above 50 PSI and flow rate over 6 GPM.

- Flexible Power Options: Can be powered by a battery bank or 110V power sources, with options for battery chargers and power supplies to suit various operational needs.

Detailed Description:

RO Water Creation

- Tank Capacity: 270-gallon IBC tank for storing RO permeate water.

- Inlet Water Requirements: Operates best with 50+ PSI and >6 GPM flow rate.

- Power Consumption: Three RO pumps drawing a total of 48 amps of 12V power (600 watts), powered by a battery bank (not included) or 110V power bricks.

- RO Permeate Storage: Independent of operator consumption, ensuring continuous water availability.

- Flush System: Includes flush valves for each RO membrane to remove excess contaminants.

Operator Pure Water Delivery

- Independent Systems: Four identical DI pure water filtration and delivery pump systems with remote control pump controllers.

- Flow Control: Each operator can adjust flow using both the pump controller and remote control fob.

- DI Resin Cartridges and TDS Meters: Ensure pure water output with zero TDS.

- Hose Compatibility: Suitable for use with reels and hoses (200-300 ft, not included).

Power Requirements and Options

- RO Pumps: Require 600 watts (48 amps of 12V power).

- Operator Pumps: Require 240 watts (20 amps of 12V power).

- Combined Power Draw: Total of approximately 1000 watts (9 amps at 110V).

- Battery Pack Options: RO battery pack needs a 40-amp charger, delivery pump battery pack needs a 20-amp charger.

- Generator Recommendation: 1800-watt generator for complete system operation.

Upgrade your water delivery system with this efficient, reliable, and versatile Pure Water Production System, perfect for professional use in various cleaning and maintenance applications.

The images below indicate the features of the system

-nxf302.jpg)

-LhFSR4.jpg)

Operator Reels (not Included) are available in several size hose lengths and hose styles

ProTool 19in Reel with 200ft of Hybrid hose

Lots of room for more hose on this large reel

ProTool Reels can be stacked to save space

ProTool Blue Braid PVC Hose 300ft 3/8in ID

A Popular choice for a delivery reel

ProTool 15in Reel with 100ft of 1/2in Inlet Hose

This is an on demand Pure Water filtration system that creates RO Permeate water from Tap Water at a rate of 4.5+ gpm (gallons per minute) into a RO water storage tank. System rating at 55psi and 6 GPM input tap water at 70 degrees or more, note the RO production system will work at lower input PSI or water flow but will produce less water.

A 4 user delivery system allows for the operator to control the water flow up to 1 GPM to their Water-Fed cleaning pole and brush.

Included:

- Delivery to 48 states

Not included:

- Power: Battery Banks or 110v Power Adaptors

- Battery Charger(s) when battery banks are used

- Operator Reel(s) and Delivery Hose(s)

- Operator Water-Fed poles

- Input water hose from Tap water source

The Spring Pump Controller is a robust and powerful part of the skid solution and is designed to manage the pump to enhance the performance and longevity of your pump while providing precise control over pump flow.

Key Features:

- Powerful Management: Capable of effectively managing pumps power draw extending battery life and ensuring reliable and efficient operation.

- Regulated Speed Control: Allows for precise regulation of pump speed, significantly reducing power consumption and mechanical wear, thus extending the pump’s lifespan.

- User-Friendly Operation: Enables effortless setting of desired flow rates and convenient on/off control directly from the unit, streamlining operations and saving time.

Why a Pump Controller is Important:

- Extended Pump Lifespan: By regulating pump speed and reducing mechanical wear, a pump controller significantly increases the operational lifespan of your pump.

- Energy Efficiency: Precise control over pump flow reduces power consumption, leading to more efficient operation and lower energy costs.

- Ease of Use: The Spring Pump Controller is easy to setup offering hassle-free operation.

Proposition 65 requires businesses to provide warnings to Californians about significant exposures to chemicals that cause cancer, birth defects or other reproductive harm. These chemicals can be in the products that Californians purchase, in their homes or workplaces, or that are released into the environment. By requiring that this information be provided, Proposition 65 enables Californians to make informed decisions about their exposures to these chemicals. Proposition 65 also prohibits California businesses from knowingly discharging significant amounts of listed chemicals into sources of drinking water. Proposition 65 requires California to publish a list of chemicals known to cause cancer, birth defects or other reproductive harm. This list, which must be updated at least once a year, has grown to include approximately 900 chemicals since it was first published in 1987. Proposition 65 became law in November 1986, when California voters approved it by a 63-37 percent margin. The official name of Proposition 65 is the Safe Drinking Water and Toxic Enforcement Act of 1986.

The list of chemicals contains a wide range of naturally occurring and synthetic chemicals that include additives or ingredients in pesticides, common household products, food, drugs, dyes, or solvents. Listed chemicals may also be used in manufacturing and construction, or they may be byproducts of chemical processes, such as motor vehicle exhaust. For more information visit www.p65warnings.ca.gov/