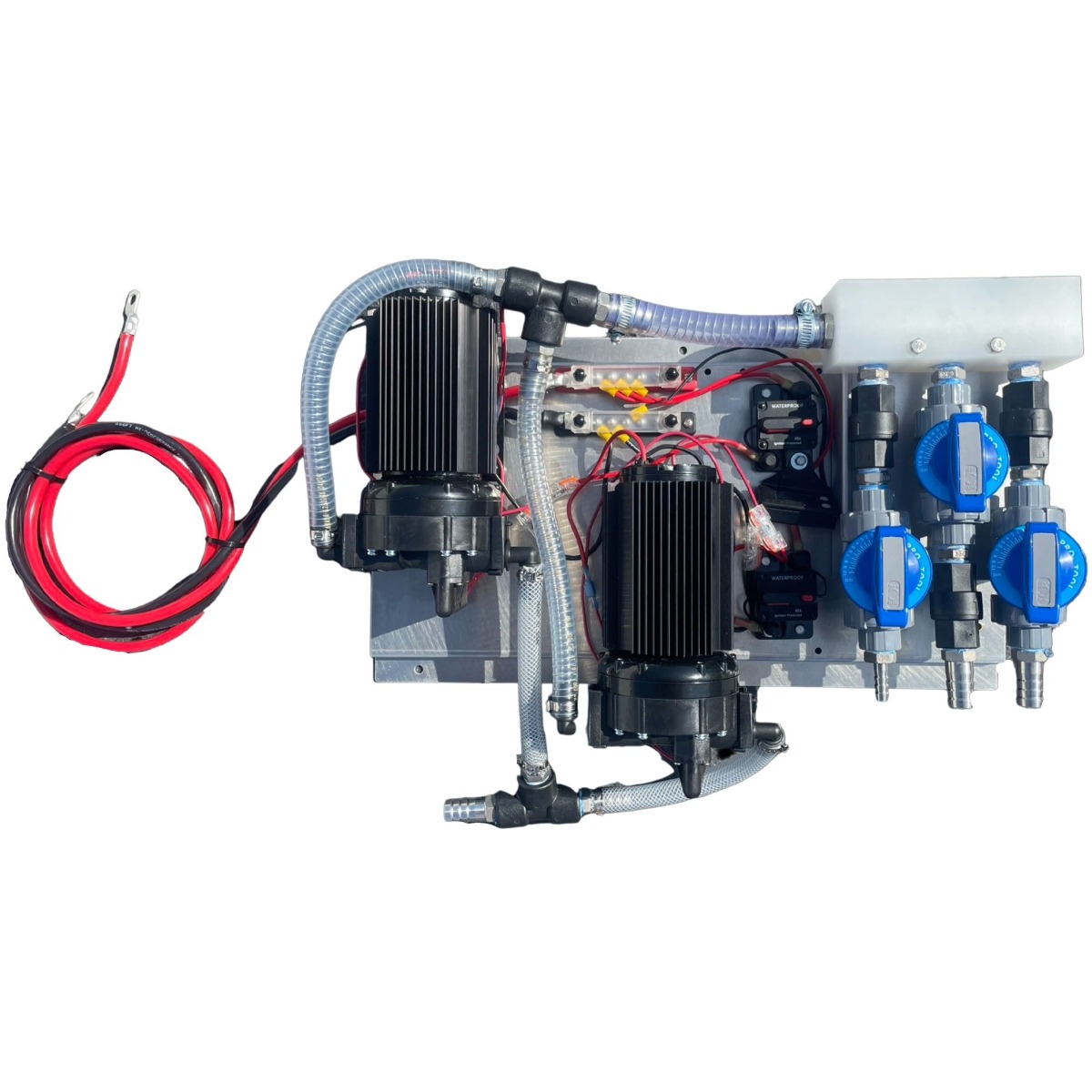

ProTool Soft Wash Metering Plates

Quick Overview

- Configured with manual or remote rinsing options and 12v or 12v+110v power options for complete build flexibility.

- Features a sophisticated metering block with adjustable valves to blend water, sodium hypochlorite (SH), and surfactants in exact proportions.

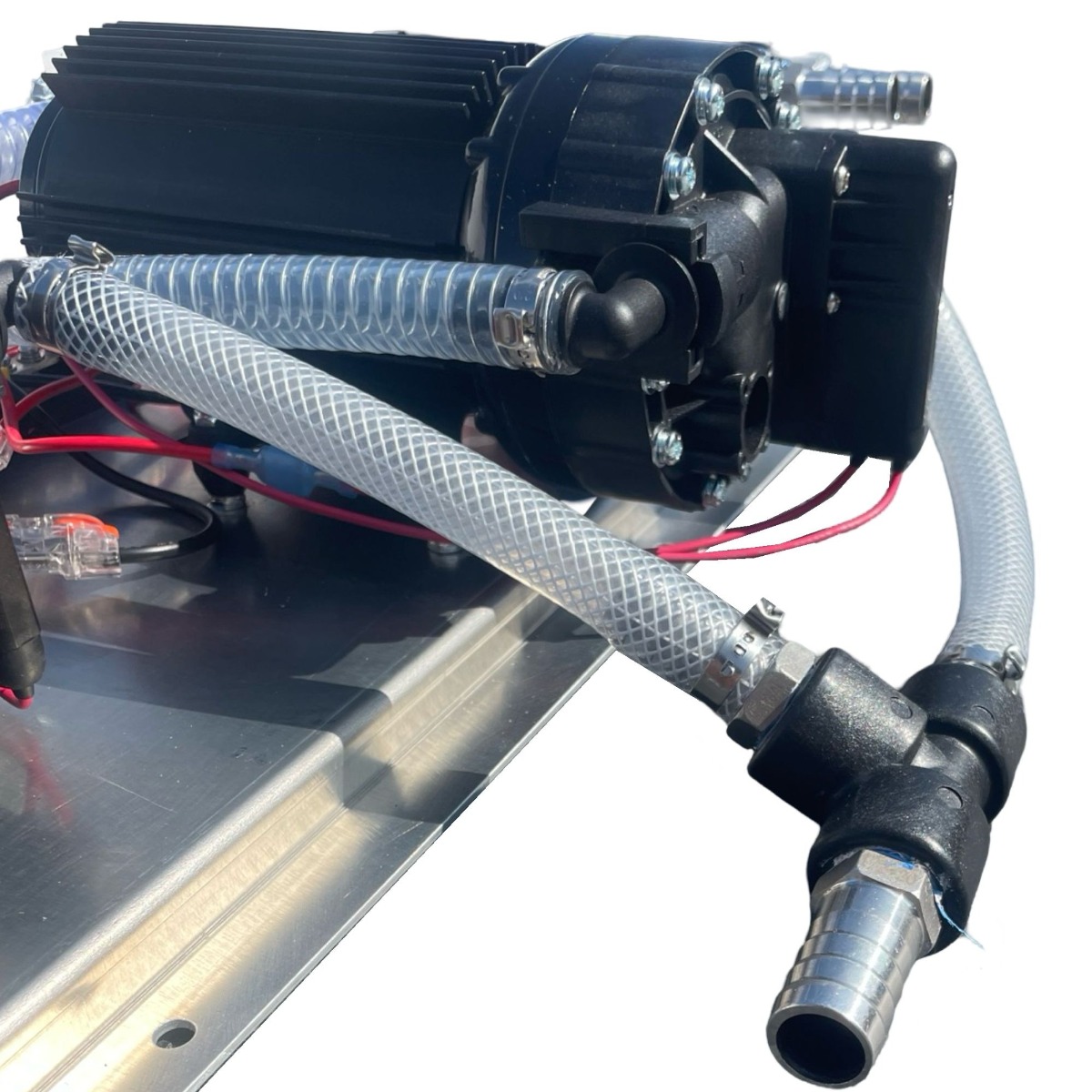

- Equipped with dual pumps that collectively deliver 7.4 GPM at 60 PSI, and can handle up to 90 PSI with approximately 4 GPM flow.

- Designed with robust 3/4-inch plumbing to maximize flow and ensure even distribution of the soft wash solution.

- Comes assembled and mounted on a ready-to-install plate, making it a straightforward addition to your DIY or custom-built soft wash setup.

Show More

$1,229.25 - $2,042.70

Configuration / Voltage Selection

Soft Wash Metering Block System

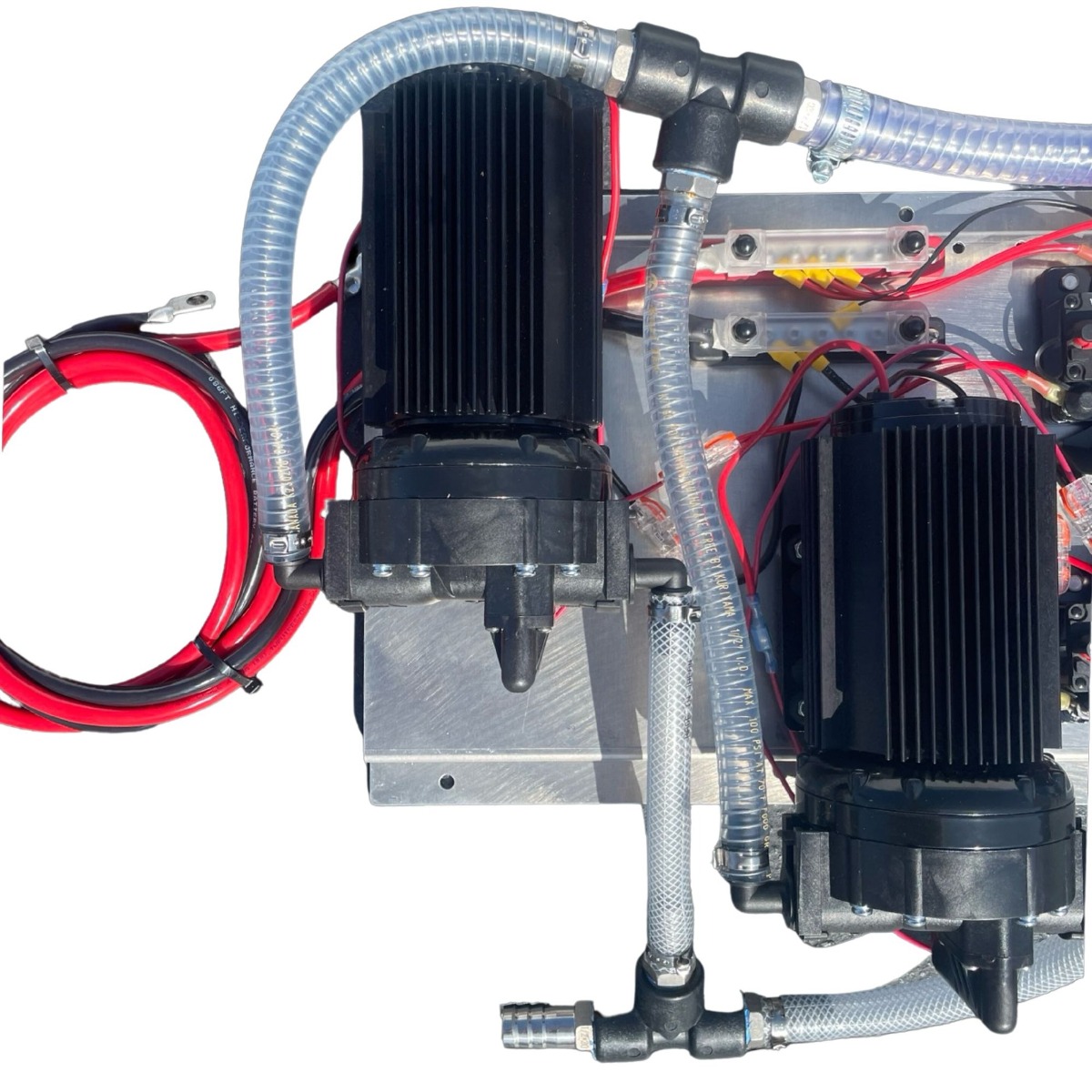

This Softwash Metering system uses a metering block and valves to blend the chemicals in the proportions desired. The plate includes dual pumps capable, together of delivering 7.4 gallons per minute (GPM) at 60 PSI, the system can run up to 90 PSI with about 4 gpm flow.

The system ensures efficient and reliable performance to meet your soft washing needs.

Featuring metering valves, the ProTool Soft Wash Metering System offers full control over water, sodium hypochlorite (SH), and surfactant ratios, allowing for precise customization of your soft wash mixture. Whether you're tackling delicate surfaces or stubborn stains, this system empowers you to achieve optimal results with ease.

With 3/4-inch plumbing, the ProTool Soft Wash Metering System maximizes flow to ensure consistent and effective distribution of your soft wash solution. This robust plumbing configuration enhances performance while minimizing downtime, allowing you to complete soft wash jobs efficiently.

Assembled, and attached to a mounting plate this is a Ready to install Metering system as part of a (DIY) or Build it yourself soft wash setup.

The ProTool Soft Wash Metering System is suitable for installation in your truck, trailer, or van. Whether you're a professional contractor or a DIY enthusiast, this system provides the flexibility and convenience you need to tackle soft wash projects with confidence.

Upgrade your soft wash operations with the ProTool Soft Wash Metering System and experience the convenience, efficiency, and performance it brings to your workflow. Whether you're cleaning residential exteriors, commercial buildings, or industrial facilities, this system is your trusted companion for achieving outstanding results every time.

Kit Highlights:

Dual 90 PSI pumps = 7.4 GPM of flow at typical 60 PSI spraying pressure

Easy to mount wall plate that's ready to mount to truck, trailer or van

Three Metering valves for full control over water, SH and Surfactant.

All parts to plumb the system from the hose barbs in through to the reel.

Spray at 4 gpm at 90 PSI.

Configurations:

Metering System: Complete Metering System with block manifold giving you full control over your mix ratios.

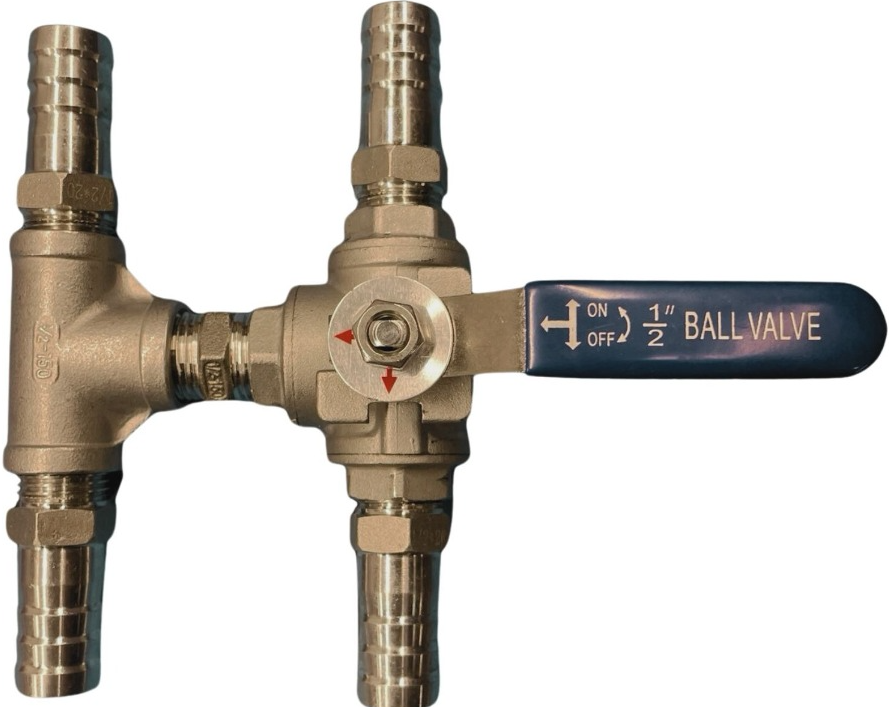

Metering System w/Manual Rinse: Complete metering system with a manual three-way valve to switch from SH and water to give more waterflow for rinsing and rinse out your check valves, and internal components simultaneously.

Metering System w/Remote Rinse: Complete metering system with a remote activated three-way valve and on/off valve for soap to automatically switching from spraying chems to rinse with two 3/4" water lines. Soap shut off also disengages soap line.

Power:

12 volt can be powered from any 12V battery. We recommend a Type or Group 31 Marine/Deep cycle battery. For extra life, run multiple batteries in a battery bank and wire them in parallel or, a lithium ion with 200AH capacity or more.

12 volt and 110V can be powered from a 12 battery or battery bank or with 110V directly with the included dual 12v power supplies. Ultimate flexibility in power options. 110v to 12V power supplies can be run indefinitely as long as you have a 110V power source via any standard wall socket or generator.

110V Power Pack comes attached to the back of the plate. Pre-wired into the electrical 12V bus bars with battery cut off switch. Give you the option run from 12V battery or a standard 12V socket. (Like a laptop)

Manual Rinse turns the bleach (SH) line into another water line to rinse out the check valves and 12V pumps, while giving you extra water flow for more rinse volume

Remote Rinse systems allows you to shut off/turn on the bleach (SH) line and the surfactant lines remotely. Easily switch from spraying chems to rinsing without the need to return to your rig.

Ships Ready to install:

This kit ships with posts for mounting the pump, electrical wiring done, and the bracket/metering system mounted.

Just install pumps and connect the quick connects, attach the leads provided to your battery and you are ready to clean.

Mounting screws required. Plate comes with 1/4" clearance holes. Pickup 6 1/4" screws with the length you need to mount to a support bar, side or divider wall.

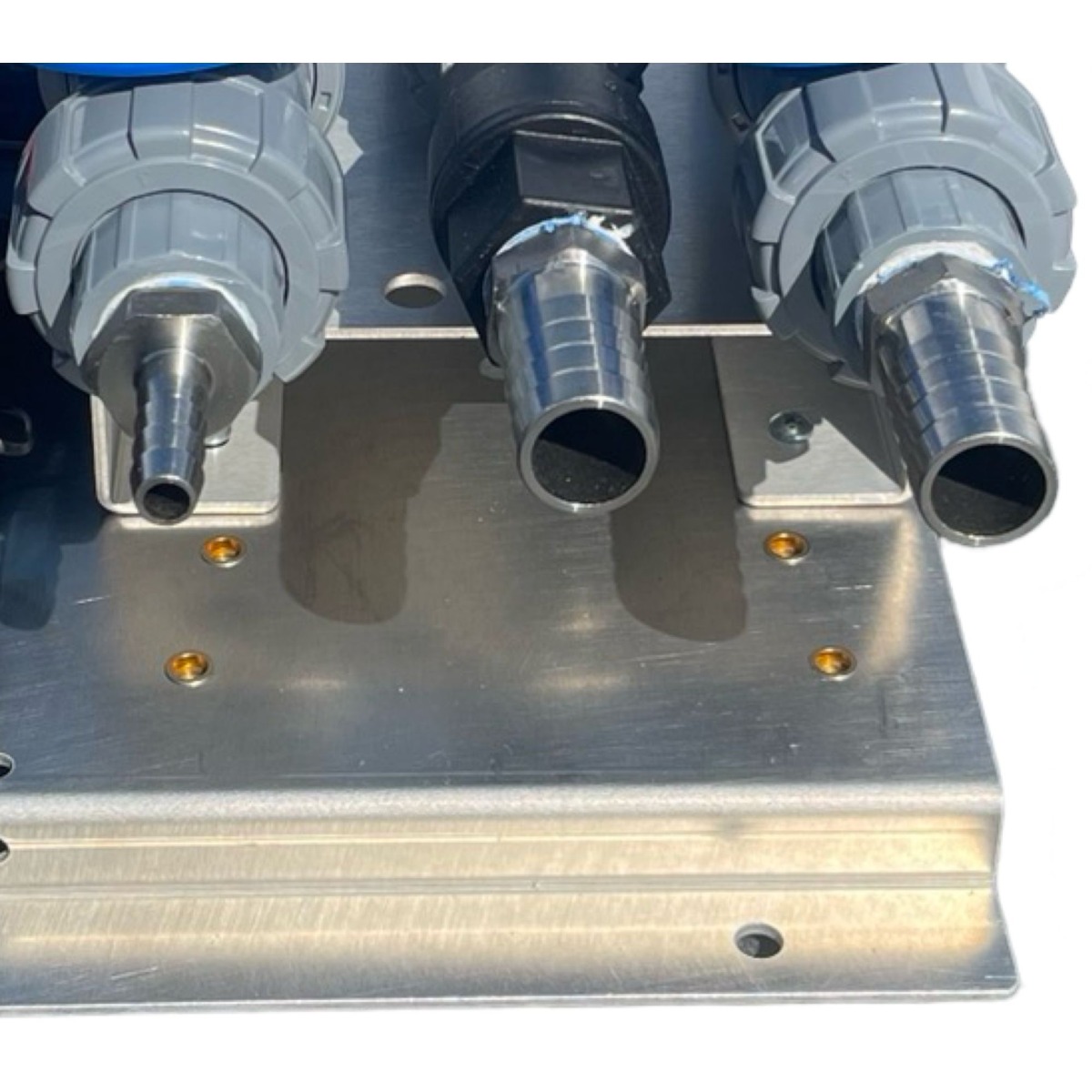

Plumbed for MAX flow:

With 3/4 in plumbing, this system is ready to output 7.4 GPM at 60PSI to the reel.

All Stainless Steel Bard offer superior chemical resistance and service life.

3/8" barb for surfactant/masking agent

3/4" barb for SH (Bleach) line

3/4" barb for water

3/4" barb for output

There is an 3/4in additional port in the manifold for use with a Pumps that requires a regulator return line. This ships with the port plugged with a 3/4in plug

Backed by Dual Pumps:

Two pumps offer a combined 7.4 GPM at 60PSI to the reel.

Dual 12V pumps offer "limp mode" if one fails. That's 3.8 GPM at 60PSI IF you see a pump failure, compared to 100% when a single pump fails.

No down time = no headaches on the job and no upset customers when equipment fails.

If you want more flow, more chemistry sprayed from the gun, increase your tip size.

This system includes the two pumps you will need for soft washing and rinsing.

You would need:

Storage Tanks and hoses for water and the input chemicals

Water + 3/4in Suction Hose from Water Tank to the Metering System

SH (sodium hypochlorite, bleach tank +1/2in Suction Hose from SH Tank to the Metering System

Surfactant (Could use 5 gallon Bucket) + 3/8in clear braid line from Surfactant tank to Metering System)

Mixing Setup - Metering Initial Setup

There is no exact science to where the valves are going to be set for your spraying needs. This will get you close to start and you will need to tune to your needs. The goal is to use as little sH and Surfactant as possible and still get a fast complete and well spread out spray that sticks to the surface from the wand.

- The Water Valve is set to 10

- The Bleach Valve is set to 10

- The Surfactant is set t0 1 to 2

- The Water Valve is set to 10

- The Bleach Valve is set to 4

- The Surfactant is set t0 1 to 2

- The Water Valve is set to 10

- The Bleach Valve is set to 2

- The Surfactant is set t0 1 to 2

6% Retail Bleach or stale 12.5% SH or Stale 10% Pool Bleach where the contents have degraded to less potency.

This can easily happen with store bought beach that was on the shelf for 6 months...

Output to the wand….

3/4in Clear Braid Line from the metering system to your Reel Swivel Barb

1/2in minimum (or better 5./8in) Clear Braid Hose on the Reel 150 to 200ft of spraying hose

Trigger Gun on end of the hose to spray with a selection of spray tips.

As shown here as part of a system:

Flow Rate Chart

Here are flow rates for various tip orifices sizes.

TIP

20

30

40

50

60

.23"

FLOW

2 GPM

3.1 GPM

4.1 GPM

5.2 GPM

6.4 GPM

7.8 GPM

DISTANCE

30 FT

33 FT

40 FT

45 FT

46 FT

42 FT

Features:

- Dual pumps capable of delivering 7.4 GPM at 60 PSI and 90 PSI, ensuring efficient soft wash operations

- ProTool Metering valves provide full control over water, sodium hypochlorite (SH), and surfactant ratios for precise customization of soft wash mixtures

- 3/4-inch plumbing maximizes flow for consistent and effective distribution of soft wash solution

- Ready-to-install DIY setup allows for easy integration into trucks, trailers, or vans

- Empowers both professional contractors and DIY enthusiasts to achieve optimal soft wash results with ease

- Robust construction and reliable performance enhance productivity and minimize downtime

- Ideal for cleaning residential exteriors, commercial buildings, and industrial facilities with outstanding efficiency and effectiveness

The plate dimensions are:

21in wide by 12in high,

- The holes in the corner are 18in wide 1.5in in from the edge on the long side

- The center hole is 10.5 in in from the edge on the long side

- The holes are 11in apart on the short side.

The installation needs 4 to 5 inches above and below the plate to accommodate the pumps and allow for clearance of the hose connections. So a 22 wide by 22 high dedicated space would be sufficient

The plate dimensions are:

21in wide by 12in high,

- The holes in the corner are 18in wide 1.5in in from the edge on the long side

- The center hole is 10.5 in in from the edge on the long side

- The holes are 11in apart on the short side.

The installation needs 4 to 5 inches above and below the plate to accommodate the pumps and allow for clearance of the hose connections. So a 22 wide by 22 high dedicated space would be sufficient

Proposition 65 requires businesses to provide warnings to Californians about significant exposures to chemicals that cause cancer, birth defects or other reproductive harm. These chemicals can be in the products that Californians purchase, in their homes or workplaces, or that are released into the environment. By requiring that this information be provided, Proposition 65 enables Californians to make informed decisions about their exposures to these chemicals. Proposition 65 also prohibits California businesses from knowingly discharging significant amounts of listed chemicals into sources of drinking water. Proposition 65 requires California to publish a list of chemicals known to cause cancer, birth defects or other reproductive harm. This list, which must be updated at least once a year, has grown to include approximately 900 chemicals since it was first published in 1987. Proposition 65 became law in November 1986, when California voters approved it by a 63-37 percent margin. The official name of Proposition 65 is the Safe Drinking Water and Toxic Enforcement Act of 1986.

The list of chemicals contains a wide range of naturally occurring and synthetic chemicals that include additives or ingredients in pesticides, common household products, food, drugs, dyes, or solvents. Listed chemicals may also be used in manufacturing and construction, or they may be byproducts of chemical processes, such as motor vehicle exhaust. For more information visit www.p65warnings.ca.gov/