How to Choose the Right Scraper Blade

Table of Contents

How to Choose the Right Scraper Blade

Not all scraping jobs are created equal—and the same goes for scraper blades. The right blade can make the difference between a quick, clean job and a frustrating, time-consuming task. Whether you’re removing paint specks, tackling hard water stains, or cleaning up after construction, different blades are designed for different challenges.

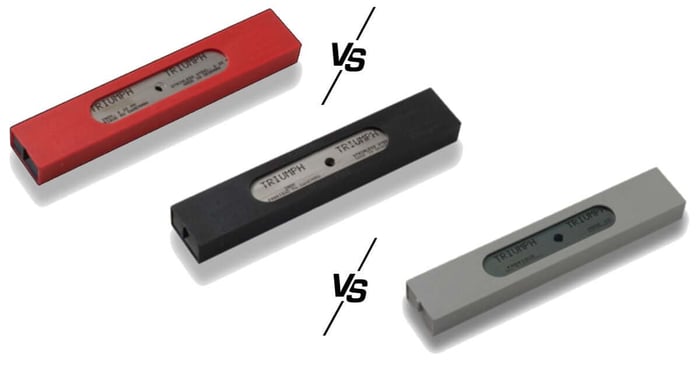

In this guide, we’ll break down the types of scraper blades—.15mm stainless steel, .20mm stainless steel, and carbon blades—so you’ll know exactly which one to reach for in every situation. By understanding the strengths and limitations of each, you can work more efficiently, extend the life of your tools, and avoid costly mistakes on the job.

.15mm Stainless Steel Blades – Flexible and Versatile

The .15mm stainless steel is the original Triumph blade, which is more flexible in the scraper. This is handy for many tasks – like removing stickers, paint speckles, hard water spots, etc. – but not as much for others. These blades are also a bit more prone to having corners broken when they run into something on the surface.

Blades Triumph Stainless Steel 06 inch 0.15 mm Thick (25 Pack)

$28.15

Blades Triumph Stainless Steel 06in Wide by 0.15mm Thick (25 Pack) – Premium Scraping Blades for Precision and Durability Upgrade your scraping toolkit with Triumph...… read more

.20mm Stainless Steel Blades – Durable Workhorses

A few years ago, JBF – manufacturer of the Triumph brand blades – was asked to create a .20 mm stainless steel blade in order to provide similar strength to carbon blades, which are also .20 mm. The .20 mm stainless steel blades have no flex to them and are truly a work horse. The thicker blades provide more toughness without having the corners chip off.

Blades Triumph Stainless Steel 06in 0.20 mm Thick (25 Pack)

$31.00

Blades Triumph Stainless Steel 06in wide by 0.20 mm Thick (25 pack) Triumph Quality Blades: The Ultimate Scraping Solution for Smooth Hard Surfaces When it...… read more

Carbon Blades – The Choice for Construction Cleanup

For construction cleanup, however, the blade of choice should be carbon. It’s a better grade of steel and will stay sharper longer during the day. However, carbon will typically rust after one use, but with post-construction work it’s not a problem because you’ll got through plenty of blades on a single job.

Blades Triumph Carbon 06 inch 0.20mm Thick (25 Pack)

$23.50

Blades Triumph Carbon Steel 06in wide by 0.20mm Thick (25 pack) Triumph Quality Blades: Exceptional Scraping Solutions for Smooth Hard Surfaces When it comes to...… read more

Just as not all blades are the same, neither are all blade manufacturers.

JBF – manufacturer of the Triumph blade – has advanced blade-making technology to create a purely perfect blade..

Just as not all blades are the same, neither are all blade manufacturers.

TLDR – Choosing the Right Scraper Blade

Different scraper blades (.15mm stainless, .20mm stainless, and carbon) are designed for specific tasks. Choosing the right one improves efficiency, safety, and results.

Key Points:

.15mm Stainless Steel Blades

Original Triumph blade.

Flexible and versatile.

Best for stickers, paint specks, and hard water spots.

More prone to corner breakage.

.20mm Stainless Steel Blades

Developed to match the toughness of carbon blades.

Rigid, no flex.

Durable “workhorse” blade for heavy use.

Less likely to chip compared to thinner blades.

Carbon Blades

Stay sharper longer during construction cleanup.

Preferred for post-construction scraping jobs.

Rusts after one use, but acceptable due to high blade turnover.

Blade Manufacturers Matter

Not all blades are equal in quality.

JBF (maker of Triumph blades) uses advanced technology for precision and durability.

Takeaway:

Match the blade type to the task:

Flexible (.15mm stainless) for light work.

Durable (.20mm stainless) for tough scraping.

Sharp (carbon) for construction cleanup.

Quality manufacturers like JBF ensure consistent performance and safety.

Additional Considerations When Choosing Scraper Blades

While blade thickness and material are the most obvious differences between scraper blades, there are other factors worth considering before stocking up for your next job. These include the type of scraper you’re using, the surfaces you’re working on, safety practices, and even the economics of blade replacement. Understanding these nuances ensures you not only get the job done but also protect both your tools and your clients’ property.

Matching Blades to the Scraper Handle

A high-quality scraper is only as good as the blade inside it. Some scrapers are designed to maximize flexibility, while others focus on rigidity for stubborn debris. For example, Triumph scrapers pair especially well with their dedicated blades, since the tolerances are exact. Using off-brand blades may save a few dollars in the short term but can lead to poor fit, uneven pressure, or premature blade wear. When possible, stick with blades made for your scraper’s manufacturer—it ensures consistent performance and reduces the risk of scratching surfaces.

Surface Sensitivity

Another key consideration is the type of surface you’ll be scraping. Glass, metal, stone, and coated finishes all respond differently to blade pressure.

Glass surfaces: The most common surface for scraper use, but also the most sensitive. A thin .15mm stainless steel blade is often preferred because it flexes slightly and reduces the chance of gouging.

Painted or coated glass: Use extreme caution. Sometimes a plastic blade is a safer choice, especially when working around decorative finishes or tinted glass.

Stone or tile: On tougher surfaces, a .20mm stainless steel or carbon blade is usually safe, as these surfaces can withstand more pressure.

The Role of Blade Angle

How you hold the scraper is just as important as the blade itself. Always maintain a shallow angle (about 30–45 degrees) when scraping glass to avoid digging into the surface. A rigid .20mm blade at the wrong angle can cause more damage than a flexible .15mm blade, even if the blade is sharper. Training technicians on the correct technique is just as important as choosing the right blade type.

Safety Best Practices

Scraper blades are razor-sharp tools, and safety should always be a priority. Always store blades in a protective dispenser or case, and never carry loose blades in a pocket or tool bag. Dull blades are actually more dangerous than sharp ones because they require more force, increasing the chance of slipping and causing injury. Regular blade changes keep work efficient and reduce the risk of accidents.

Cost vs. Performance

It can be tempting to stretch the life of a blade, but in professional cleaning, blade replacement is often the more economical choice. For example, carbon blades may rust quickly, but their sharpness during a single heavy-use day can save hours of labor. Likewise, switching from a chipped .15mm stainless blade to a fresh one costs pennies but saves the frustration of streaks, scratches, or missed spots. Professionals should view blades as consumables—like squeegee rubbers—rather than tools meant to last indefinitely.

When to Use Plastic Blades

Though not covered in the main breakdown, plastic blades also have their place in a cleaner’s toolkit. They’re ideal for delicate surfaces like glass cooktops, tinted windows, or painted surfaces where even a flexible stainless blade may be too aggressive. Plastic blades won’t stay sharp for long, but they provide a safe alternative when working on specialty surfaces.

Training and Standardization

For companies with multiple technicians, it’s important to standardize blade use across teams. Establishing clear guidelines—such as when to use .15mm versus .20mm blades—reduces mistakes and ensures consistent results for clients. Training sessions on scraper safety and blade selection can also help newer employees build confidence and avoid costly errors.

Final Word

Choosing the right scraper blade goes far beyond just grabbing whatever is on hand. By understanding the differences in thickness, material, fit, and application, you can maximize both safety and efficiency. Whether it’s the flexibility of .15mm stainless steel, the toughness of .20mm stainless, the sharpness of carbon, or even the gentle touch of plastic blades, each option has its time and place. Stocking multiple blade types and training your team to use them correctly ensures you’re ready for any challenge—whether it’s post-construction cleanup, delicate glass maintenance, or routine spot scraping.

In the end, scraper blades are small tools with a big impact. Choosing wisely saves time, protects property, and delivers the professional results that set your services apart.

FAQs

What is the difference between .15mm and .20mm stainless steel scraper blades?

.15mm stainless blades are flexible and ideal for light scraping tasks like stickers, paint speckles, and water spots. .20mm stainless blades are thicker, tougher, and less likely to chip, making them better for heavy-duty jobs.

When should I use carbon scraper blades instead of stainless steel?

Carbon blades are the best choice for construction cleanup because they stay sharper longer. However, they do rust quickly, so they’re typically used for single-job applications.

Do thicker scraper blades last longer?

Yes, thicker blades like the .20mm stainless steel or carbon blades tend to hold up longer under tough use, but the right choice depends on the job and surface.

Why do stainless steel scraper blades chip more easily?

Thin stainless blades (.15mm) are flexible, which makes them versatile but also more prone to corner breakage when scraping rough or uneven surfaces.

Are all scraper blade brands the same?

No, blade quality varies by manufacturer. For example, JBF (maker of Triumph blades) uses advanced blade-making technology for more precise, durable edges.

Can I reuse carbon scraper blades?

You can, but most pros don’t. Carbon blades tend to rust after one use, which is why they’re often replaced frequently, especially on post-construction jobs. If you are looking for blades that last longer use stainless steel blades. the .2 mm blades are a good balance between strength and longevity.