DI Resin Life, RO-DI Examples Pure Water Cleaning

Table of Contents

Pure Water Cleaning: DI Resin Life, TDS, and When You Need an RO/DI System

Pure water cleaning (waterfed pole cleaning) works because 0 TDS water dries spot-free—no minerals left behind on glass, panels, or фасades. The challenge is cost: the higher your incoming TDS, the faster your DI resin gets consumed.

If you’re deciding between a DI-only tank and a multi-stage RO/DI system, this guide will make it simple—with practical sizing tips and a resin-life table you can use in the field.

What Is TDS (and Why It Controls DI Resin Life)

TDS (Total Dissolved Solids) is a measurement of dissolved minerals in water, expressed in PPM. In pure water window cleaning, your DI stage must remove those dissolved solids to reach 0 TDS output—and every PPM removed uses up resin capacity.

Rule of thumb:

- Higher TDS in = shorter DI resin life

- Lower TDS in = longer DI resin life

DI-Only vs RO/DI: The Cost Difference Starts With TDS

DI-only systems (single stage)

DI-only can work when:

Your feed water is low-to-moderate TDS, and/or

You use the system infrequently (ex: 1–2 days per week)

But in hard-water markets, DI-only becomes expensive fast.

RO/DI multi-stage systems (recommended for high-TDS + frequent use)

A proper RO/DI setup runs water through:

Pre-filter (often carbon)

RO membrane (removes the majority of dissolved solids)

DI resin (final polish to 0 TDS)

JRacenstein notes RO/DI systems commonly remove ~98% of impurities at the RO stage, dramatically reducing how much costly DI resin you burn through.

“Efficient RO membranes” and the 15–40 TDS target

In real-world waterfed cleaning, an efficient RO membrane (with high rejection) often outputs low-TDS permeate before DI polishing.

A practical way to think about it:

If the RO stage removes ~98% of dissolved solids, the remaining ~2% can land you in the ~15–40 TDS range depending on your incoming TDS, membrane condition, and operating pressure.

This is the whole point of RO in a professional setup: DI resin is no longer doing the heavy lifting—DI becomes the “finishing” stage. JRacenstein specifically calls out that RO can drastically cut DI consumption (even “up to 90%”) in many scenarios.

DI Resin Cartridge Size Matters (a lot)

Bigger resin volume = more exchange capacity = longer run time between swaps.

If you’re using small cartridges, you’ll experience:

More frequent resin changes

Higher cost per gallon

More downtime on jobs

If you’re running daily (or in high-TDS regions), resin volume becomes a major part of ROI.

DI Resin Life Table (Estimated Gallons to 0 TDS)

The table below estimates how many gallons you can produce before resin is exhausted, based on a standard mixed-bed DI capacity formula used in industry resources.

Assumptions: estimates vary with water chemistry, flow rate, channeling, temperature, and your “change-out” endpoint.

Estimated DI output (gallons) by feed TDS + resin vessel size

| Feed Water TDS (PPM) | 2.5 x 10in Cartridge 0.03 cu ft resin | 4.5 x 10in Cartridge 0.10 cu ft resin | 4.5 x 20in Cartridge 0.20 cu ft resin |

|---|---|---|---|

| 15 TDS | ~277 gal | ~923 gal | ~1,847 gal |

| 40 TDS | ~104 gal | ~346 gal | ~693 gal |

| 200 TDS | ~21 gal | ~69 gal | ~139 gal |

What this means in the real world:

If RO gets you down into the 15–40 TDS range, DI lasts multiples longer than it would at 200 TDS feed.

At 200 TDS feed (DI-only), small resin volumes can be burned up shockingly fast.

RO Membrane Performance: Flow Rate + Productivity

In a professional RO/DI cart or skid, membrane selection affects:

How much water you can make per day (production rate)

How well it rejects dissolved solids (how hard DI has to work)

Whether you need booster pressure for peak performance

JRacenstein highlights that RO membranes are the “backbone” of modern pure water cleaning and that rejection rate and flow can materially affect performance and operating cost.

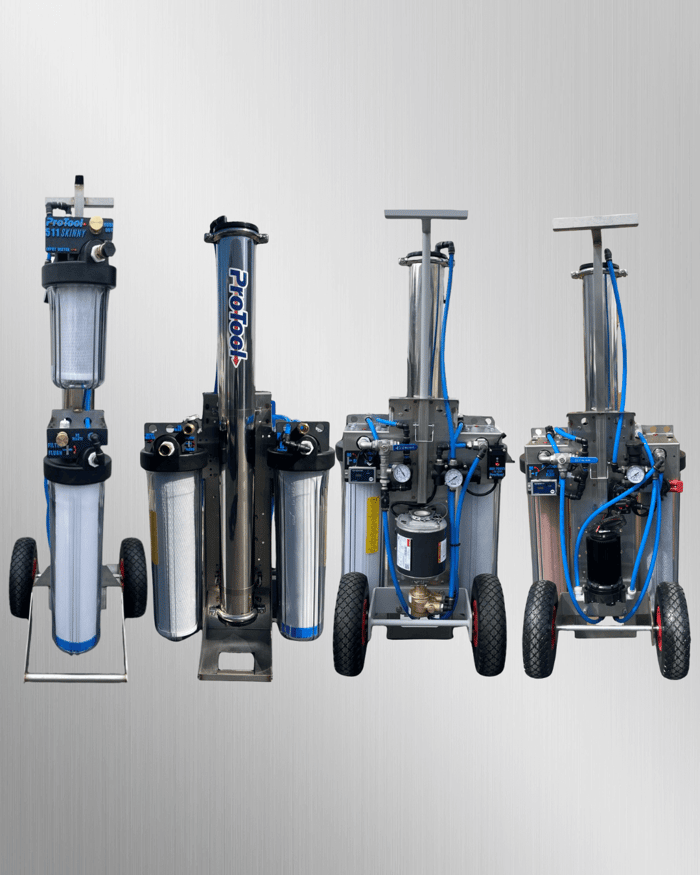

Pure Water Systems are available as Carts, Wall Mounts, Skids, or Custom Builds

Pure Water Truck and Wall Mounts

FAQs

What TDS requires RO/DI instead of DI-only?

If you’re above ~150–200 TDS and cleaning regularly, RO/DI is usually the most cost-effective approach long-term because it reduces DI resin consumption dramatically.

Why does DI resin run out so fast in hard-water areas?

Because DI resin capacity is finite, and high TDS means more dissolved solids to remove per gallon—so the resin is used up faster.