Pressure Washing vs Soft Washing

Table of Contents

- Defining the Methods: High-Impact Force vs. High-Impact Chemistry

- Head-to-Head Comparison: A Technical Breakdown for Pros

- Job Suitability: Matching the Method to the Surface

- The Great Debate: Can You Soft Wash with a Pressure Washer?

- Gearing Up: Essential Equipment for Both Methods

- Equipping Your Business for Any Cleaning Challenge

-

- FAQs

On any given job site, the line between a flawless clean and costly property damage is often determined by a single choice. The debate between pressure washing vs soft washing techniques is a constant for the professional tradesman. Using the wrong method on delicate surfaces like asphalt shingles or vinyl siding can lead to irreversible damage, jeopardizing both the client's property and your company's reputation. This guide is built for professionals who understand these high stakes and demand precision in their work.

Here, we provide the definitive breakdown. We will dissect the critical differences in equipment, PSI levels, and chemical formulations. You will gain the confidence to select the correct cleaning method for any exterior surface, understand the capabilities and limitations of your current setup, and know exactly what professional-grade equipment is necessary to expand your services safely and effectively. Master these principles to deliver superior results, protect your clients' investments, and build a reputation for unmatched expertise.

Defining the Methods: High-Impact Force vs. High-Impact Chemistry

In the professional exterior cleaning industry, the distinction between pressure washing and soft washing is a source of frequent confusion. For the tradesman, however, understanding this difference is not just about terminology—it's about results. The core choice comes down to Force vs. Finesse. Applying the wrong method can lead to catastrophic failures, including permanently damaged siding, stripped paint, broken window seals, and voided roof warranties. The success of any job hinges on understanding two critical metrics: PSI (Pounds per Square Inch) and GPM (Gallons Per Minute).

What is Professional Pressure Washing?

Professional pressure washing is a high-impact cleaning method that relies almost exclusively on mechanical force to achieve results. It uses a high-pressure stream of water to physically blast away dirt, grime, loose paint, and other tough buildup from surfaces. The focus is on the sheer power of the water jet, making it the go-to solution for durable materials that can withstand the intense force without being damaged.

- Primary Mechanism: High-pressure mechanical force.

- Best Applications: Hard, durable surfaces like concrete driveways, stone patios, brick walls, and commercial walkways.

- Typical PSI Range: 2000-4000+ PSI.

What is Professional Soft Washing?

Professional soft washing is a low-pressure cleaning technique that prioritizes chemistry over force. This method uses a specialized pump system to apply professional-grade cleaning solutions at low pressure. These solutions do the heavy lifting by breaking down and neutralizing organic growth like mold, mildew, algae, and moss. After a short dwell time, the surface is gently rinsed with clean water. Mastering the pressure washing soft wash distinction is critical for any serious contractor.

- Primary Mechanism: High-impact chemical solutions.

- Best Applications: Delicate surfaces like vinyl siding, roof shingles, stucco, wood decks, and painted surfaces.

- Typical PSI Range: Under 500 PSI, often comparable to a standard garden hose.

Head-to-Head Comparison: A Technical Breakdown for Pros

For any professional, the debate isn't about which method is superior; it's about selecting the correct tool for the specific job. Using high pressure on a delicate surface is as inefficient and damaging as trying to clean a stained driveway with low pressure. Understanding the core operational differences between pressure washing soft wash techniques is fundamental to delivering professional-grade results, protecting client property, and maximizing job site efficiency.

This quick-reference table breaks down the essential technical differences for busy contractors.

| Feature | Pressure Washing | Soft Washing |

|---|---|---|

| Pressure (PSI) | High (1500 - 4000+ PSI) | Low (< 500 PSI, often garden hose pressure) |

| Flow Rate (GPM) | Lower (2-5 GPM) | Higher (5-12+ GPM) |

| Chemical Use | Optional; typically mild detergents for degreasing. | Essential; biocides, algaecides, and surfactants. |

| Application | Hard, durable surfaces like concrete, brick, and stone. | Delicate surfaces like roof shingles, vinyl siding, and wood. |

| Equipment | Gas or electric pressure washer, high-pressure hose, wands, and color-coded nozzles. | Dedicated 12V or gas pump systems, proportioners, and low-pressure spray nozzles. |

Pressure (PSI) vs. Flow Rate (GPM)

The primary distinction lies in force versus volume. Pressure washing prioritizes high PSI to physically blast away dirt, grime, and stains from resilient surfaces. Soft washing, conversely, prioritizes a higher GPM. This high flow rate is crucial for applying cleaning solutions over large areas quickly and, more importantly, for thoroughly rinsing away chemicals and dislodged organic matter without damaging the substrate. Think of it this way: pressure washing is a hammer, while soft washing is a solvent.

Cleaning Agents: Detergents vs. Biocides

Pressure washing relies on mechanical force, so any chemicals used are typically supplemental detergents that help break down grease and oil. Soft washing is a chemistry-based cleaning method. It depends on professional-grade biocides, most commonly Sodium Hypochlorite (SH), to kill organic growth like mold, mildew, and algae at the root. These solutions are often blended with surfactants—specialized soaps that help the chemical mix cling to vertical surfaces, increasing dwell time and effectiveness.

Equipment & Nozzles: The Right Tools for the Right Force

A standard pressure washer setup includes a heavy-duty wand and a set of color-coded nozzles (0°, 15°, 25°, 40°) that constrict water flow to create high pressure. A dedicated soft wash system uses a completely different configuration, often built around a 12V electric or gas-powered diaphragm pump designed for chemical compatibility and high flow. Using a pressure washer's high-pressure nozzle to apply soft wash chemicals is a common but critical mistake that can atomize caustic solutions, creating a safety hazard and failing to properly saturate the surface.

Job Suitability: Matching the Method to the Surface

A professional's primary responsibility on any job site is to deliver exceptional results without causing property damage. The first step is always a thorough assessment of the surface material and the type of organic or inorganic staining present. This initial diagnosis dictates the proper method. Making the right call between pressure washing soft wash techniques is what separates a seasoned professional from a novice and ensures the longevity of the client's property.

High-Pressure Applications: When Power is the Solution

High-pressure washing is the go-to solution for durable, hard surfaces where the primary goal is to remove deeply embedded dirt, grime, and loose material through sheer force. This method is about physical removal, using high PSI to blast away contaminants.

Use Pressure Washing For:

- Concrete & Masonry: Ideal for cleaning driveways, sidewalks, patios, and parking garages. It effectively removes oil stains, tire marks, and heavy buildup from porous concrete.

- Hardscapes: The professional choice for unpainted brick, stone retaining walls, and pavers where organic growth and dirt have taken deep root.

- Surface Preparation: Unmatched for stripping failing paint and rust from wood or metal surfaces prior to refinishing and repainting.

- Heavy Equipment: The most efficient method for cleaning caked-on mud, grease, and grime from construction vehicles and industrial machinery.

Never Use Pressure Washing On: Roof shingles, vinyl siding, stucco, or any painted surface you do not intend to strip. The high PSI will cause irreversible damage, void warranties, and force water into wall cavities.

Low-Pressure Applications: Precision Cleaning with Chemistry

Soft washing relies on professional-grade cleaning solutions to do the heavy lifting. It's a high-volume, low-pressure method that cleans and sanitizes delicate surfaces, killing organic growth at the root without the risk of high-pressure damage.

Use Soft Washing For:

- Roofing Systems: The only industry-approved method for cleaning asphalt shingles, tile, and metal roofs. It safely eliminates black streaks caused by Gloeocapsa magma algae without dislodging granules.

- Siding & Building Exteriors: Perfect for vinyl, aluminum, stucco, EIFS, and wood siding. It cleans away mildew, algae, and dirt without chipping paint or damaging the material.

- Painted & Delicate Surfaces: Safely cleans painted wood, fences, decks, and composite decking without stripping the finish or splintering the wood.

- Screen Enclosures: The ideal technique for cleaning lanais and pool screens without tearing the delicate mesh material.

Never Use Soft Washing For: Stripping thick, flaking paint or removing deep-set grease stains from concrete. These jobs require the mechanical force that only a pressure washer can provide.

The Great Debate: Can You Soft Wash with a Pressure Washer?

This is one of the most common points of confusion for professionals in the exterior cleaning industry. The short answer is yes, you can perform a version of soft washing with a pressure washer, but it comes with critical limitations. The method is called downstreaming, and while it’s a viable starting point, understanding its constraints is essential for delivering professional, high-quality results and knowing when to invest in dedicated equipment.

Downstreaming Explained: Pros and Cons

Downstreaming uses a chemical injector installed after the pump on your pressure washer. As high-pressure water flows through the line, it creates a vacuum (the venturi effect) that siphons cleaning solution from a separate container into the water stream. This method is common for entry-level work but has clear trade-offs.

- Pros: It’s an inexpensive way to apply cleaners using your existing pressure washer. It’s suitable for light-duty house washing on surfaces like vinyl siding where a heavily diluted chemical mix is sufficient.

- Cons: The chemical dilution is significant, often 10:1 or higher, which is not strong enough for treating heavy organic growth like gloeocapsa magma on roofs. Pulling harsh chemicals like sodium hypochlorite through your system can also cause premature wear on injectors, O-rings, and other components.

Dedicated Systems: The Professional Standard

A professional-grade, dedicated soft wash system operates independently of a pressure washer. These units use specialized pumps—typically 12V electric, air-diaphragm, or gas-powered—to deliver cleaning solutions at low pressure (around 60-100 PSI) but at a high volume (high GPM). The key advantage is control. You can apply precisely mixed, full-strength chemicals directly to the surface without dilution from a pressure washer, ensuring maximum cleaning power for tough jobs. This is the professional standard for any serious pressure washing soft wash operation.

When to Upgrade from Downstreaming to a Dedicated System

Moving from a downstream injector to a dedicated system is a crucial step in scaling your business. The decision to upgrade becomes clear when you encounter the limitations of downstreaming on the job. Consider upgrading your gear if:

- You are starting to clean roofs regularly, which requires stronger, non-diluted chemical batches.

- You need more potent mixes to effectively treat tough organic stains like thick algae, moss, or lichen.

- You want to increase job speed and efficiency, as dedicated systems apply and rinse solution much faster on large residential or commercial properties.

When your business is ready to move beyond the limitations of downstreaming and deliver faster, more effective results, investing in the right equipment is the next logical step. Ready to upgrade? Explore our dedicated soft wash systems.

Gearing Up: Essential Equipment for Both Methods

Understanding the theory behind pressure washing and soft washing is the first step. The next is investing in the professional-grade equipment that delivers consistent, high-quality results for your clients. A proper rig is not an expense; it's an investment in efficiency, safety, and profitability. At J Racenstein, we provide the complete, heavy-duty solutions professionals rely on to get the job done right.

Whether you are building your first truck or upgrading an existing setup, having a dedicated system for each method is key. A professional pressure washing soft wash arsenal ensures you can tackle any surface, from a delicate historic roof to a grimy concrete driveway, with absolute confidence.

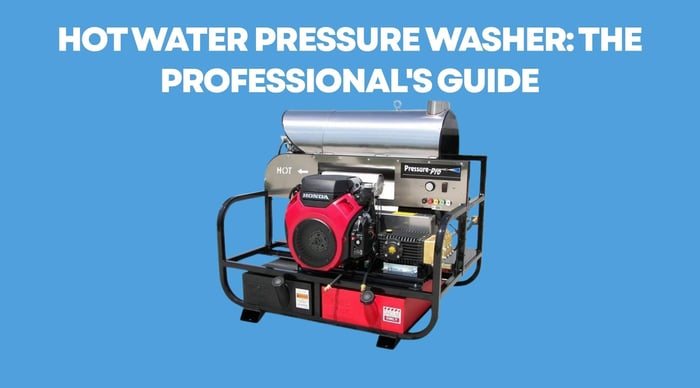

The Core Professional Pressure Washing Rig

For high-impact cleaning on durable surfaces like concrete, brick, and stone, a powerful pressure washing system is non-negotiable. The core of this setup is a robust, high-output machine designed for continuous commercial use.

- The Pressure Washer Unit: A gas-powered unit delivering at least 4 Gallons Per Minute (GPM) at 4000 PSI is the industry benchmark for professional performance and efficiency.

- Essential Accessories: Your rig is incomplete without a professional surface cleaner for flatwork, high-pressure hoses, versatile wands, and a comprehensive nozzle kit for adjusting spray patterns and pressure.

Equip your operation with durable, high-performance tools built for the trade. Shop our complete range of professional pressure washing equipment.

The Complete Professional Soft Wash System

A dedicated soft wash system is engineered for the precise, low-pressure application of cleaning solutions. This method relies on chemistry, not force, making specialized equipment essential for safety and effectiveness on surfaces like roofing, siding, and wood.

- The Pump: Choose from reliable 12V electric, high-flow gas-powered, or air-diaphragm pumps based on your required flow rate and power source.

ProTool Pump 90psi 5.0gpm Demand Switch Spraying

$194.60

ProTool Pump 90psi 5.0gpm Demand Switch SprayingIntroducing the ProTool Pump, a reliable and efficient solution for spraying chemicals with precision and ease. This quality pump...… read more

- The Proportioning System:This is the heart of soft washing, allowing you to accurately mix water, surfactant, and sodium hypochlorite on the fly for perfect, repeatable results.

Soft Wash Metering Block

$516.60

Soft Wash Metering Valve System Soft Wash Metering Valve Mixing Manifold Block: High Flow up to 13gpm with Precision Control for Professional Soft Washing This...… read more

- Tanks and Hoses: You will need dedicated, properly-sized poly tanks for water and chemicals, along with chemical-resistant hoses that won't degrade from exposure to cleaning agents.

Get a system perfectly tailored to your business needs. Build your custom soft wash skid with our expert team.

Equipping Your Business for Any Cleaning Challenge

Mastering exterior cleaning comes down to knowing your tools and your surfaces. The key takeaway is clear: pressure washing relies on high-impact force for durable materials, while soft washing leverages high-impact chemistry for delicate surfaces like roofing and siding. Making the right choice protects your client's property and solidifies your professional reputation. Ultimately, understanding the distinct applications for pressure washing soft wash methods is what separates the amateur from the expert.

When you're ready to build a versatile, high-performance setup, J. Racenstein is your partner. As the trusted supplier to thousands of cleaning professionals, we offer more than just parts. Our in-house experts provide essential advice on equipment and custom builds, backed by a massive inventory of professional-grade brands. Equip your business for any job. Shop our professional pressure washing and soft wash supplies.

Arm yourself with the right gear and expertise, and you’ll be prepared to deliver exceptional results on every project.

FAQs

What PSI is officially considered soft washing?

Soft washing is defined by its low pressure, which is typically below 500 PSI. Most professional soft wash systems operate in the 100 to 300 PSI range, a pressure comparable to that of a strong garden hose. This is a significant contrast to high-pressure washing, which can easily exceed 3,000 PSI. The effectiveness of soft washing comes from the cleaning solution, not the force of the water, making it a safe method for delicate surfaces.

Is soft washing or pressure washing better for cleaning a house's vinyl siding?

Soft washing is the superior and industry-recommended method for cleaning vinyl siding. High-pressure washing can force water behind the siding panels, leading to moisture intrusion, mold, and mildew growth within the walls. It can also cause irreversible damage like cracking, etching, or dislodging the siding. Soft washing uses specialized detergents to eliminate organic growth and grime safely, cleaning the surface thoroughly without the risk of damage from high-impact force.

Can you damage a roof by pressure washing it?

Yes, you can cause severe and costly damage by pressure washing a roof, especially one with asphalt shingles. The high-pressure stream strips away the protective granules that shield the shingle from UV rays, drastically shortening the roof's lifespan and often voiding the manufacturer's warranty. The only method recommended by the Asphalt Roofing Manufacturers Association (ARMA) for roof cleaning is soft washing, which eliminates algae and stains without causing destructive granule loss.

What are the primary chemicals used in a professional soft wash mix?

A professional soft wash solution is primarily based on sodium hypochlorite (SH), which is the active ingredient in bleach, to kill mold, mildew, algae, and other organic growth. This is blended with water and a professional-grade surfactant. The surfactant, or soap, helps the solution cling to vertical surfaces for increased dwell time, break down surface tension for better penetration, and mask the chemical odor. The exact ratios depend on the surface being cleaned.

What is the main safety difference between pressure washing and soft washing?

The primary safety risk in pressure washing is the high-velocity water stream, which can cause serious laceration or injection injuries and easily damage property. For soft washing, the main safety concern shifts to chemical handling. Professionals must use appropriate Personal Protective Equipment (PPE), including chemical-resistant gloves, eye protection, and sometimes respirators, to prevent skin and eye irritation from contact with sodium hypochlorite and other cleaning agents. Both methods require professional training to execute safely.