Choosing an Effective Rust Remover

Table of Contents

- Understanding Rust Stains: Identifying the Source for Proper Treatment

- Types of Professional Rust Removers: A Chemical Breakdown for Pros

- How to Choose the Right Rust Remover for Any Surface

- Professional Application Techniques and Best Practices

- Safety Protocols and Property Protection: The Mark of a True Pro

- Your Professional Solution for Rust Removal

-

- FAQs

As a professional, you know that one wrong chemical can turn a profitable job into a costly liability. Etched concrete, bleached siding, or damaged landscaping are risks that can destroy your reputation and your bottom line. When tackling stubborn exterior stains, selecting the right professional-grade rust remover is critical. It’s not just about cleaning-it’s about demonstrating expertise, protecting your client’s property, and ensuring a flawless finish every time.

This guide provides the essential knowledge to operate with confidence and precision. We will break down the different types of rust removers, from heavy-duty acids to safer, surface-specific synthetics. You’ll learn exactly which solution to use on vinyl, brick, metal, and other common surfaces to achieve perfect results without causing damage. Arm yourself with the right information to work more safely, increase job profitability, and solidify your status as an industry expert.

Understanding Rust Stains: Identifying the Source for Proper Treatment

For the exterior cleaning professional, not all rust stains are created equal. While a homeowner might see a simple orange blemish, a tradesman must see a specific problem requiring a targeted solution. A foundational understanding of what rust is-the result of iron or its alloys oxidizing-is the first step, but identifying the source of that iron is what dictates your chemical approach and ensures a successful, damage-free outcome.

For a practical demonstration of different rust removers in action, view the video below:

Common Culprits: Fertilizer, Battery Acid, and Metal Runoff

Diagnosing the stain's origin is critical for selecting a high-performance chemical. The four most common sources on exterior surfaces each have a distinct signature:

- Fertilizer Stains: Caused by iron granules in many lawn fertilizers that get scattered onto concrete. They appear as small, concentrated orange speckles.

- Battery Acid Stains: Resulting from leaks in golf carts, scissor lifts, or other machinery. These are often darker, appearing as deep brown or blackish stains that have leached into the surface.

- Metal Runoff: Identifiable by vertical streaks running down from metal components like steel flashing, screws, HVAC units, or decorative ironwork.

- Well Water/Irrigation Stains: Often appear as widespread, uniform orange or brown discoloration on siding, retaining walls, and sidewalks from sprinkler systems using iron-rich water.

Why Surface Type Matters in Rust Removal

The substrate you are cleaning is as important as the stain itself. Porous materials like unfinished concrete and brick absorb stains deep into their matrix, requiring a rust remover that can penetrate effectively without causing spalling or discoloration. Conversely, non-porous or sensitive surfaces like vinyl siding, painted metal, or EIFS can be etched or permanently damaged by overly aggressive acids. Using the wrong product can turn a simple rust removal job into a costly surface replacement, making proper chemical selection essential for professional results.

Source of Rust | Commonly Affected Surfaces | Typical Appearance |

|---|---|---|

Fertilizer Granules | Concrete Driveways, Patios, Pavers | Small, orange, speckled "freckles" |

Battery Acid | Garage Floors, Concrete, Asphalt | Deep, dark brown or blackish stains |

Metal Runoff | Siding, Stucco, Concrete Walls | Vertical orange or brown streaks |

Irrigation/Well Water | Siding, Fences, Retaining Walls | Widespread, uniform orange discoloration |

Types of Professional Rust Removers: A Chemical Breakdown for Pros

For professional exterior cleaners, selecting the right rust remover goes far beyond grabbing a generic product off the shelf. True effectiveness lies in understanding the active chemical ingredients and how they interact with both the rust and the substrate. Rust, or iron oxide, is an alkaline compound. Acid-based removers work by using a low-pH solution to chemically dissolve and break down this bond. However, the type of acid and its concentration dictate its power, speed, and potential for collateral damage. Proper pH management and post-treatment neutralization are critical to prevent etching and ensure a clean, stable surface.

Acid-Based Removers: The Industry Standard

Acid-based formulas are the workhorses of the rust removal industry due to their rapid and decisive action. However, not all acids are created equal, and using the wrong one can cause irreversible damage. Handling these potent chemicals demands strict adherence to professional Safety Protocols and the use of appropriate Personal Protective Equipment (PPE).

- Oxalic Acid: A powerful organic acid, this is the go-to solution for removing stubborn rust stains from porous surfaces like concrete, brick, and masonry. It is highly effective but must be handled with caution and thoroughly rinsed.

- Phosphoric Acid: This ingredient is unique because it doesn't just dissolve rust; it converts it into a stable, black ferric phosphate coating. This makes it an ideal choice for treating metal surfaces prior to painting. Professional-grade products like F9 BARC utilize a phosphoric acid base for reliable, consistent results.

- Hydrochloric/Muriatic Acid: This is an extremely aggressive and corrosive inorganic acid. While it acts fast, the risk of fuming, etching concrete, and damaging surrounding materials is exceptionally high. Its use is rarely recommended outside of highly specific industrial applications by seasoned experts.

Acid-Free & pH-Neutral Alternatives

For jobs where surface integrity is the absolute priority, acid-free rust stain removers provide a high-performance, low-risk solution. Instead of using acid to dissolve rust, these advanced formulas employ chelating agents. In simple terms, these agents chemically bind to iron oxide particles, lifting them from the surface so they can be rinsed away without altering the substrate itself.

- Benefits: Significantly safer for delicate or high-value surfaces such as polished stone, historic masonry, EIFS, and vinyl siding. They pose less risk to adjacent sensitive landscaping and eliminate the danger of acid etching.

- Drawbacks: These formulas often act more slowly than acids, requiring longer dwell times. On extremely deep or layered rust stains, their effectiveness may be more limited compared to a targeted acid treatment.

How to Choose the Right Rust Remover for Any Surface

Selecting the correct chemical solution is critical for effective rust removal and for preserving the integrity of the substrate. A formula that works perfectly on concrete can cause irreversible damage to vinyl siding or a painted metal roof. For any professional-grade application, your first step should always be to test your chosen rust remover on a small, inconspicuous area to confirm compatibility and desired results.

This guide provides a direct, surface-by-surface breakdown to help you select the right product for the job.

Concrete and Masonry (Brick, Pavers)

Porous, durable surfaces like concrete and brick require a powerful chemical to lift embedded rust stains. Oxalic acid-based products are the industry standard for this application due to their high-performance cleaning action.

- Recommended Chemical: Oxalic Acid-Based Cleaners

- Application Pro-Tip: Always pre-wet the concrete or masonry surface with water. This prevents the acid from etching the surface and ensures it works only on the stain.

- Professional Precaution: Be aware of creating a "too clean" spot. To avoid a blotchy finish, feather the chemical agent out from the stain and consider cleaning a larger, defined section to ensure a uniform appearance.

Vinyl Siding, Stucco, and EIFS

These materials are far more sensitive to aggressive chemicals than masonry. Using a high-strength acid can lead to discoloration, pitting, or permanent damage. The professional approach is to start with the mildest effective option and proceed with caution.

- Recommended Chemical: Start with an acid-free or buffered, low-strength acidic rust remover specifically formulated for sensitive surfaces.

- Critical Steps: Carefully manage the chemical's dwell time-do not let it dry on the surface. Rinse thoroughly with low pressure to neutralize the reaction and remove all residue.

Painted Surfaces, Metal Roofs, and Fencing

The primary challenge here is removing the rust without stripping the paint or protective coating. A product that is too aggressive will damage the finish, exposing more metal and leading to further corrosion. The goal is targeted rust removal while preserving the coating.

- Recommended Chemical: Phosphoric acid-based removers are often suitable as they convert the iron oxide (rust) into a stable, paintable phosphate layer. Neutral pH rust removers are also an excellent, safe option.

- Post-Treatment: After treatment, ensure the surface is properly neutralized and dry. Applying a new protective coating or sealant is often necessary to prevent rust from returning.

Professional Application Techniques and Best Practices

Selecting a high-performance rust remover is only half the battle. For professional, repeatable results, your application technique is just as critical. The right process ensures maximum efficiency, prevents surface damage, and delivers the clean substrate your clients expect. Mastering dilution, application, and rinsing separates the professional from the amateur and guarantees the best performance from your chosen chemical. How you apply the product is just as important as the product itself.

Dilution Ratios and Dwell Time

Always consult the product label for specific dilution ratios. As a professional best practice, start with a weaker mix for a test spot on an inconspicuous area, strengthening the solution only if required. This prevents potential surface etching. Dwell time is crucial for effectiveness; never allow the solution to dry, as the chemical reaction will stop. Keep the surface damp with a light mist of water or additional product to ensure the chemical works to its full potential.

Application Tools: Pump Sprayer vs. Down streaming

Your choice of tool depends on the job's scale. For precision on small, concentrated stains, a professional pump-up sprayer provides unmatched control. For larger surfaces, avoid down streaming harsh, acidic chemicals, as this can corrode your pressure washer pump and internal components. A superior method is using an X-Jet or a dedicated chemical injector that applies the solution after the pump, protecting your heavy-duty equipment. Shop our professional-grade sprayers and chemical injectors to find the right solution for your rig.

Rinsing and Neutralization

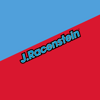

A thorough rinse is non-negotiable for a clean finish. Use a pressure washer with a low-pressure fan tip (e.g., a 25 or 40-degree tip) to gently wash away the chemical and the dissolved rust. Avoid using high pressure, which can drive the stain deeper into porous concrete or masonry. On sensitive materials or before applying a sealer, apply a neutralizing agent like a soda ash solution to completely halt the chemical reaction and ensure surface stability.

Safety Protocols and Property Protection: The Mark of a True Pro

Using a professional-grade rust remover effectively is only half the job. The other half-the part that separates seasoned professionals from amateurs-is an unwavering commitment to safety. A meticulous protocol not only protects you and your team but also builds client trust and safeguards your reputation. It demonstrates a level of care and expertise that justifies a premium service.

Essential Personal Protective Equipment (PPE)

Never underestimate the chemical composition of powerful rust removal agents. Equipping yourself with the right professional-grade PPE is non-negotiable. Your standard kit should always include:

- Acid-Resistant Gloves: Heavy-duty nitrile or butyl rubber gloves provide the best chemical barrier.

- Eye and Face Protection: At a minimum, wear splash-proof safety goggles. For jobs with a high risk of spray or splatter, a full-face shield is essential.

- Respiratory Protection: In enclosed or poorly ventilated areas, a NIOSH-approved respirator with appropriate cartridges is critical to prevent inhalation of harmful fumes.

- Durable Clothing: Wear waterproof boots, long sleeves, and pants to protect your skin from accidental contact.

Protecting the Client's Property

A true professional leaves a property in better condition than they found it, with no collateral damage. Before applying any rust remover, implement a systematic property protection plan. This includes pre-saturating all grass, shrubs, and plants with water to dilute any accidental overspray. Use heavy-duty plastic sheeting to cover delicate vegetation, windows, and painted doors. Always be mindful of runoff, using sandbags or water diversion tubes to direct chemical waste away from storm drains and sensitive waterways. A thorough, low-pressure rinse of all surrounding surfaces and plants after the job is complete is the final step in a professional application.

Proper chemical management extends beyond the job site. Always store products according to manufacturer specifications in a secure, well-ventilated area. Adhere strictly to all local and federal regulations for the disposal of used chemicals and contaminated rinse water. This commitment to compliance is a hallmark of a reliable and trustworthy operation. For a complete lineup of professional-grade safety gear and cleaning solutions, visit jracenstein.com.

Your Professional Solution for Rust Removal

Choosing the right rust remover is a mark of true professionalism in the exterior cleaning industry. As this guide has detailed, achieving flawless results depends on a systematic approach: correctly identifying the stain's source, understanding the different chemical compositions available, and meticulously matching the product to the surface in question. This knowledge, combined with professional application techniques and strict adherence to safety protocols, ensures you not only remove the stain but also protect the property and enhance your reputation.

When you're ready to put this knowledge into action, J Racenstein provides the professional-grade tools you need to succeed. We are proud to stock industry-leading brands trusted by seasoned professionals for their consistent, high-performance results. Need guidance? Our expert support is available for product selection. With our fast shipping, you can get the essential chemicals you need delivered directly on-site, minimizing downtime and maximizing efficiency. Shop our complete line of professional-grade rust removers today and equip your business to conquer any challenge.

FAQs

Can I use a rust remover through my pressure washer's downstream injector?

Most professional-grade, acid-based rust removers should not be run through a downstream injector. The acidic solution can corrode the internal components of your pressure washer, including the pump, seals, and injector itself, leading to premature failure. This method also over-dilutes the product, reducing its effectiveness. For optimal results and equipment longevity, always apply these chemicals using a dedicated acid-resistant pump-up sprayer, a soft wash system, or a compatible proportioner like an X-Jet.

Will professional rust removers kill grass and other plants?

Yes, acid-based rust removers can cause significant damage or kill grass, shrubs, and other vegetation upon contact. The chemical composition can burn plant leaves and disrupt soil pH. To prevent damage, professionals must take precautions. Thoroughly pre-wet all surrounding plant life with water, cover sensitive plants with plastic sheeting, and immediately rinse any overspray. After the job is complete, a final, heavy rinse of the area is essential to dilute any remaining chemical runoff.

How do I neutralize a concrete surface after using an acid-based rust remover?

Neutralizing the surface is a critical final step after using an acid-based rust remover on concrete. This process stops the chemical reaction and prevents a white, chalky residue from forming. Apply a professional-grade neutralizer or a high-alkaline soap, such as a heavy-duty degreaser, to the affected area. Allow it to dwell for 5-10 minutes before performing a final, thorough rinse with your pressure washer. This ensures the concrete's pH is balanced and ready for sealing if required.

Can rust stains be removed from asphalt shingles without causing damage?

Removing rust from asphalt shingles requires a precise, low-pressure approach. Aggressive chemicals or high-pressure rinsing will dislodge the protective granules and permanently damage the roof. Use a professional rust remover specifically rated as safe for shingles, applied with a soft wash system or pump-up sprayer. Allow the product to dwell per manufacturer instructions, then rinse gently with low pressure. Always test on an inconspicuous area first to ensure there is no discoloration or adverse effect on the shingle.